SGPGB1000 Metal Surface and Edge All-in-One Solution

Professional sander manufacturer

There are specialties in the technical industry, we focus on the research and development of sanders to provide users with a large number of options.If you want choose for sheet metal deburring machines, wide belt grinding machines Manufacturer, please contact us.

Perfect processing technology

Suitable for all kinds of materials

High quality after sales service

Professional &

trustworthy

A wide range of applications

Electric power parts industry, automotive precision parts, non-metallic insulation board, friction materials, precision sheet metal manufacturing, rail transit equipment manufacturing, aerospace, nuclear power and other special materials processing, engineering, agricultural machinery, plate processing, medical equipment.

Equipment introduction

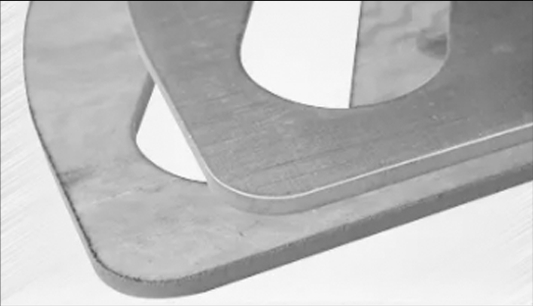

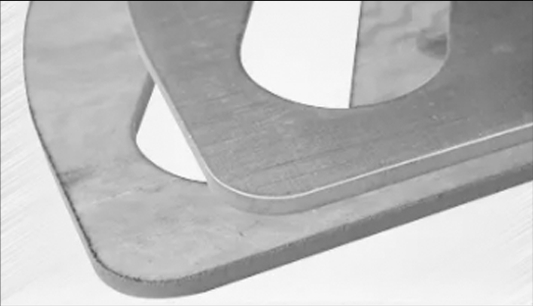

Our equipment is suitable for processin g workpieces of various materials, such as copper, aluminum, stainless steel and mild steel, etc.

It is specially used for batch burr removal, edge blunting, surface polishing, surface drawing, etc. of laser cutting blanking parts. The core grinding station adopts up to four grinding methods, which can be used in combination to greatly improve processing efficiency.

SGPGB1000 Metal Surface and Edge All-in-One Solution

SGP1300 Wide abrasive belt head for sanding out the burrs or surface finishing,Planetary type abrasive barrel station for further edge rounding, 8 abrasive barrels (4 in clockwise rotation, and 4 in counter-clockwise rotation), and planetary rotation.

SGP1300 High efficiency deburring edge rounding and surface finishing machine

SD-H is suitable for small batch parts deburring and edge rounding. It has much better working efficiency, and more consistent performance than traditional hand held angle grinder or orbital sander. It does a fantastic job on deburring and edge rounding of laser cutting, punching, stamping, and some flat machined parts.

JONSEN SMART DEBURRING AND FINISHING MACHINE SD-H

It is used for batch burr removal, blunting of sharp edges and corners, surface polishing, etc.

The core grinding station is ground with a powerful wide abrasive belt combined with a flexible grinding roller group to achieve a continuous and uniform grinding effect. The high-efficiency and clean processing characteristics are suitable for the workpiece to enter the next process such as hemming, surface spraying, welding, etc., eliminating the inefficiency, flying dust, and inconsistent workpiece grinding that exist in manual grinding. The conveying system adopts vacuum adsorption type, which can meet the batch processing of the same thickness and multiple specifications.

Efficient metal deburring edge rounding and finishing machine SGP1300

Application solution

Cutting and punching flat workpieces with rounded corners

Plasma, flame, laser dross, slag removal

Surface rust removal, laser oxide removal

News

Company news

and industry information

Maximizing Productivity: Integrating Cutting and Punching Corner Rounding Machines into Workflow Systems

Integrating cutting and punching corner rounding machines into workflow systems offers numerous benefits for businesses in various industries. These machines automate and streamline the process of cutting and rounding corners, saving time and increasing productivity.

One of the key benefits of integration is improved efficiency. By combining these machines with workflow systems, companies can eliminate manual tasks and reduce human error. This leads to faster production times and higher quality output.

Integrating these machines also allows for better resource allocation. Companies can optimize their production line by assigning the right tasks to each machine, ensuring maximum output and reducing waste.

Moreover, integrating cutting and punching corner rounding machines enables businesses to stay competitive in today's fast-paced market. By leveraging automation and technology, companies can meet customer demands more efficiently and deliver products on time.

In conclusion, integrating cutting and punching corner rounding machines into workflow systems is crucial for maximizing productivity, streamlining processes, and staying ahead in the competitive market.

Integrating cutting and punching corner rounding machines into workflow systems provides businesses with a range of benefits. By automating tasks and streamlining processes, these machines enhance productivity and efficiency.

One major benefit is the reduction in manual labor and human error. By automating cutting and punching tasks, companies can eliminate the risk of mistakes and ensure consistent output. This not only saves time but also improves the quality of the finished product.

Integrating machines also allows for better resource allocation. Companies can optimize their production line by assigning the appropriate tasks to each machine. This ensures a smooth flow of work and reduces waste, ultimately maximizing output and reducing costs.

Furthermore, integrating machines in workflow systems enables businesses to stay competitive in a fast-paced market. By leveraging automation and technology, companies can meet customer demands more efficiently and deliver products on time.

Overall, integrating cutting and punching corner rounding machines into workflow systems offers significant benefits, including increased productivity, improved quality, better resource allocation, and a competitive edge in the market.

Integrating cutting and punching corner rounding machines into workflow systems has a significant impact on productivity and efficiency. By automating tasks and streamlining processes, these machines eliminate the need for manual labor, resulting in increased productivity.

With the use of cutting and punching machines, companies can achieve faster production cycles and meet deadlines more effectively. These machines also reduce the risk of human error, ensuring consistent and accurate output.

Additionally, by integrating machines into workflow systems, companies can optimize resource allocation. Each machine can be assigned specific tasks based on its capabilities, resulting in a smooth flow of work and minimizing waste. This not only maximizes output but also reduces costs.

Moreover, machines offer faster turnaround times, allowing businesses to respond quickly to customer demands. By leveraging automation and technology, companies can stay competitive in a fast-paced market and provide timely delivery of products.

Overall, the integration of cutting and punching corner rounding machines into workflow systems significantly improves productivity and efficiency, leading to enhanced business performance.

Cutting and punching corner rounding machines come in various types, each designed for specific functions and applications. Understanding the different types can help businesses select the right machine for their workflow needs.

By understanding the different types of cutting and punching corner rounding machines, businesses can choose the right machine that aligns with their specific workflow requirements and enhances their productivity.

Cutting machines are essential tools that play a crucial role in various industries. They utilize different mechanisms to deliver precise and clean cuts in materials such as paper, fabric, plastic, and more. Guillotine cutters are widely used for straight-edge cuts and are commonly found in print shops, packaging, and graphic design industries. Rotary cutters, on the other hand, are versatile and can handle different thicknesses and types of materials, making them popular in textile, quilting, and crafts industries. These machines consist of a rotating blade that smoothly cuts through the materials.

The integration of cutting machines into workflow systems offers numerous benefits. They enhance productivity by automating cutting processes, reducing manual labor, and ensuring consistent and accurate results for every project. With the ability to handle a variety of materials, cutting machines allow for faster production and improved efficiency. They also contribute to a safer work environment by minimizing the risk of accidents associated with manual cutting methods.

By integrating cutting machines into their workflow systems, businesses can optimize their operations, save time and costs, and deliver high-quality products to their customers.

Punching machines are a vital component of automated workflow systems in industries such as printing, binding, and packaging. These machines efficiently create holes, slots, or perforations in materials like paper, cardboard, and plastic.

Punching machines come in various types, including manual, electric, and hydraulic options. Manual machines are suitable for low-volume punching needs, while electric and hydraulic machines are designed for higher production volumes.

These machines offer precision and consistency in hole placement and size, ensuring uniformity in finished products. They are equipped with adjustable settings to accommodate different hole patterns and sizes, making them versatile for a wide range of applications.

By integrating punching machines into workflow systems, businesses can eliminate manual punching tasks, leading to faster production times and reduced labor costs. Additionally, punch machines with corner rounding capabilities can provide a seamless finish to rounded edges, adding a professional touch to printed materials and packaging. Overall, the integration of punching machines enhances productivity, improves efficiency, and delivers high-quality products.

Workflow optimization strategies are essential to maximize the efficiency and productivity of your integrated cutting and punching corner rounding machines. By streamlining processes and maximizing output, businesses can achieve significant time and cost savings.

One key strategy is to analyze and optimize workflows to identify bottlenecks and areas for improvement. This may involve reorganizing workstations, adjusting machine settings, or implementing automation software to streamline operations.

Another strategy is to implement standardized operating procedures and train employees on best practices for using the machines. This ensures that everyone follows consistent processes, reducing errors and increasing efficiency.

Additionally, regularly monitoring and analyzing data from the machines can provide valuable insights for further optimization. This includes tracking machine performance, identifying maintenance needs, and analyzing production trends to make informed decisions on workflow adjustments.

By implementing these workflow optimization strategies, businesses can achieve increased productivity, improved quality, and reduced costs, ultimately gaining a competitive edge in the market.

Integrating cutting and punching corner rounding machines into workflow systems offers businesses the opportunity to streamline their processes and increase efficiency. These machines automate repetitive tasks, eliminate the need for manual labor, and reduce the risk of errors.

By integrating these machines into the workflow, businesses can optimize the production process. For example, cutting machines can precisely cut materials according to predetermined measurements, saving time and ensuring consistent results. Punching machines can quickly create holes or shapes in materials, further accelerating the production process.

Moreover, these machines can also be integrated with software systems to automate the entire workflow, from design to production. This eliminates the need for manual data entry and reduces the risk of human error. The integration of machines with automation software allows for seamless coordination and synchronization, leading to increased productivity and output.

Overall, streamlining processes with cutting and punching corner rounding machines significantly improves productivity, reduces costs, and enhances the overall efficiency of the workflow system.

Integrating cutting and punching corner rounding machines into workflow systems not only streamlines processes but also maximizes output. By seamlessly integrating these machines with software systems, businesses can achieve higher levels of productivity and efficiency.

Integrated systems allow for the automation of the entire workflow, from design to production. This eliminates the need for manual data entry and reduces the risk of human error. The machines work in harmony with the software, ensuring seamless coordination and synchronization, resulting in increased productivity.

Furthermore, these integrated systems enable businesses to optimize the use of resources and reduce waste. With precise cutting and punching capabilities, materials are utilized efficiently, reducing costs and maximizing output.

By leveraging the power of integrated systems, businesses can experience significant improvements in productivity and overall output. The combination of cutting and punching corner rounding machines with automation software allows for a smooth and efficient workflow, ultimately leading to increased profitability and customer satisfaction.

When it comes to selecting the right cutting and punching corner rounding machines for your workflow, there are several factors to consider. By carefully evaluating your specific needs and requirements, you can choose machines that will contribute to optimal productivity and efficiency.

For cutting machines, consider factors such as cutting speed, accuracy, and versatility. Look for machines with advanced cutting capabilities like laser or waterjet cutting, as well as automated features like material handling systems. Additionally, consider the size and thickness of materials you will be working with, as well as the volume of production.

When selecting punching machines, consider factors such as punching force, speed, and die options. Look for machines with high punching capacity, quick changeover capabilities, and customizable die options to accommodate various shapes and sizes.

It is also important to assess the compatibility of the machines with your existing workflow systems and software. Ensure that the machines can seamlessly integrate with your software systems to automate processes and streamline production.

By carefully considering these factors, you can select the right cutting and punching corner rounding machines that align with your specific workflow requirements and contribute to maximum productivity and efficiency.

When selecting cutting machines for your workflow, there are several important considerations to keep in mind. First, consider the cutting speed and accuracy of the machines. Look for machines that can cut materials quickly and precisely to maximize productivity and ensure high-quality results. The versatility of the machines is also crucial. Choose machines that offer a range of cutting capabilities, such as laser cutting or waterjet cutting, to accommodate different materials and projects.

The size and thickness of the materials you will be working with is another important factor. Ensure that the chosen machines can handle the dimensions of your materials effectively. Additionally, consider the volume of production. If you have high production demands, opt for machines that can handle large quantities of materials efficiently.

Furthermore, it is important to assess the compatibility of the cutting machines with your existing workflow systems and software. Look for machines that can seamlessly integrate with your software systems and automate processes, saving time and effort.

By considering these factors, you can select cutting machines that align with your specific workflow requirements, ensuring optimal productivity and efficiency.

When it comes to choosing punching machines for your workflow, there are several important considerations to keep in mind. First, consider the specific punching capabilities that are required for your projects. Different punching machines offer various capabilities, such as hole punching, notching, or embossing. Evaluate your needs and choose a machine that can effectively handle the types of punches you require.

Another important consideration is the size and thickness of the materials you will be working with. Ensure that the chosen punching machines can accommodate the dimensions of your materials effectively. Additionally, consider the volume of production. If you have high production demands, opt for machines that can handle large quantities of punching efficiently.

Furthermore, it is crucial to assess the compatibility of the punching machines with your existing workflow systems and software. Look for machines that can seamlessly integrate with your software systems and automate processes, saving time and effort.

By considering these factors, you can select punching machines that align with your specific workflow requirements, ensuring optimal productivity and efficiency.

To ensure the longevity and optimal performance of cutting and punching corner rounding machines, proper maintenance and care are essential. Here are some tips to keep your machines in top-notch condition:

By following these maintenance and care tips, you can ensure that your cutting and punching corner rounding machines operate efficiently and consistently, maximizing their lifespan and performance.

Proper maintenance practices are crucial for ensuring the long-term performance and efficiency of cutting and punching corner rounding machines. Here are some essential tips to keep in mind:

By implementing these proper maintenance practices, you can maximize the longevity and optimal performance of your cutting and punching corner rounding machines, resulting in enhanced productivity and efficiency.

To ensure the longevity and optimal performance of cutting and punching corner rounding machines, proper maintenance practices are crucial. Regular cleaning is essential to remove dust, debris, and residue that can accumulate and affect the functionality of the machines. Lubrication should be done as per the manufacturer's recommendations to reduce friction and prevent excessive wear and tear. Regular inspections should also be conducted to identify any signs of wear, damage, or misalignment and address them promptly to prevent further damage. It is important to provide operator training on proper usage, maintenance, and troubleshooting techniques to prevent potential breakdowns. Following the manufacturer's recommended maintenance schedule for routine inspections, tune-ups, and part replacements is also key to extending the lifespan of the machines and preventing unexpected downtime. By implementing these maintenance practices, the longevity and optimal performance of cutting and punching corner rounding machines can be ensured, resulting in enhanced productivity and efficiency.

In conclusion, the integration of cutting and punching corner rounding machines into workflow systems offers various benefits, such as improved productivity and efficiency. By streamlining processes and maximizing output, these machines enhance workflow optimization and provide a competitive edge in the market.

When selecting cutting and punching machines, it is important to consider factors such as the specific requirements of the workflow, cutting precision, punching capacity, and compatibility with other equipment.

Maintenance practices play a vital role in ensuring the longevity and optimal performance of these machines. Regular cleaning, lubrication, and inspections help prevent breakdowns and reduce downtime. Following the manufacturer's recommended maintenance schedule and providing operator training are essential for maintaining the machines' functionality.

In the future, advancements in workflow automation may introduce more innovative features and improved integration capabilities for cutting and punching machines. By staying updated with these trends, businesses can continue to maximize productivity and stay ahead in the industry.

In conclusion, the integration of cutting and punching corner rounding machines into workflow systems offers significant benefits, including improved productivity and efficiency. These machines streamline processes, optimize workflow, and provide a competitive edge in the market. To maximize the benefits, it is important to carefully consider the specific requirements of the workflow, the cutting precision and punching capacity needed, and the compatibility with other equipment. Proper maintenance practices, such as regular cleaning, lubrication, and inspections, are crucial in ensuring the longevity and optimal performance of the machines. Following the manufacturer's recommended maintenance schedule and providing operator training are essential. The future of workflow automation holds promising advancements, which will likely introduce more innovative features and improved integration capabilities for cutting and punching machines. Staying updated with these trends allows businesses to continuously maximize productivity and stay ahead in the industry.

As technology continues to evolve, the future of workflow automation holds promising advancements for cutting and punching corner rounding machines. Manufacturers are constantly striving to introduce more innovative features and improved integration capabilities, making it easier than ever to maximize productivity.

One trend to watch out for is the incorporation of artificial intelligence (AI) and machine learning (ML) into workflow systems. These technologies have the potential to analyze data, optimize processes, and make autonomous decisions to improve overall efficiency.

Another advancement to anticipate is the integration of cloud computing and Internet of Things (IoT) capabilities. This will enable real-time monitoring and control of machines, allowing for remote management and predictive maintenance to minimize downtime.

Furthermore, the future may bring enhanced compatibility between different machines and software systems, making it easier to integrate cutting and punching corner rounding machines into existing workflows.

By staying updated with these future trends and advancements, businesses can stay ahead in the industry, continuously maximize productivity, and maintain a competitive edge.

Exploring the Cost and Time Savings of Cutting and Punching Corner Rounding Machines

|

Importance of Corner Rounding Machines Types of Corner Rounding Machines Cost Savings with Corner Rounding Machines Time Savings with Corner Rounding Machines |

Corner rounding machines play a crucial role in various industries where precise cutting and punching are required. These machines are designed to give a professional and polished finish to materials such as paper, plastic, and leather. Their importance lies in the efficiency and precision they offer in producing rounded corners in a quick and accurate manner.

One of the main benefits of corner rounding machines is that they eliminate the need for manual labor, reducing the risk of human errors and increasing productivity. Additionally, these machines can handle a large volume of work with consistent results, ensuring a streamlined workflow process.

The importance of corner rounding machines can also be seen in the cost and time savings they provide. By reducing material waste and lowering production costs, businesses can maximize their profits. Furthermore, these machines increase production speed, allowing for faster project turnaround times and improved customer satisfaction.

Overall, corner rounding machines are valuable tools that contribute to the efficiency, precision, and cost-effectiveness of businesses in various industries.

Corner rounding machines offer a wide range of benefits that make them essential tools for businesses. With the use of these machines, businesses can achieve a professional and polished finish on materials such as paper, plastic, and leather.

One of the key advantages of corner rounding machines is their ability to eliminate the need for manual labor. By automating the cutting and punching process, these machines reduce the risk of human errors and increase overall productivity. Moreover, they can handle large volumes of work with consistent results, ensuring a streamlined workflow process.

Another significant benefit of corner rounding machines is the cost savings they provide. These machines help to reduce material waste by accurately cutting and punching corners, thereby maximizing the usage of materials and minimizing unnecessary scrap. Additionally, by streamlining the production process and increasing efficiency, businesses can lower their overall production costs.

In terms of time savings, corner rounding machines offer increased production speed. With their quick and accurate cutting and punching capabilities, these machines can significantly reduce project turnaround times, leading to improved customer satisfaction.

Overall, the benefits of using corner rounding machines include increased efficiency, reduced production costs, minimized material waste, and faster project completion. These machines are crucial for businesses looking to achieve cost and time savings while maintaining a high standard of quality and precision.

Corner rounding machines are known for their efficiency and precision in cutting and punching. These machines are designed to automate the process, eliminating the need for manual labor and reducing the risk of human error. By using a corner rounding machine, businesses can achieve consistent and accurate results every time.

The cutting and punching capabilities of these machines are quick and precise, ensuring a professional and polished finish on materials such as paper, plastic, and leather. This not only saves time but also ensures that the end product meets the highest quality standards.

Moreover, corner rounding machines streamline the workflow process by handling large volumes of work with ease. This allows businesses to increase their productivity and meet growing demands without compromising on quality. With these machines, businesses can optimize their operations and achieve remarkable cost and time savings.

In conclusion, corner rounding machines provide the efficiency and precision needed for cutting and punching materials. By incorporating these machines into their workflow, businesses can achieve consistent results, increase productivity, and save valuable time and resources.

There are two main types of corner rounding machines: manual corner rounding machines and automatic corner rounding machines.

Manual corner rounding machines are operated by hand and require manual labor to feed the material into the machine and operate the cutting mechanism. These machines are ideal for smaller-scale productions and situations where flexibility and customization are required. Manual corner rounding machines are often used in small businesses, craft shops, and print shops.

On the other hand, automatic corner rounding machines are powered by electricity and have automated feeding and cutting mechanisms. These machines are designed for high-volume production and can handle larger quantities of materials with minimal human intervention. Automatic corner rounding machines are widely used in larger manufacturing facilities, printing companies, and packaging industries.

Both manual and automatic corner rounding machines offer precision and efficiency in cutting and punching materials, but the choice depends on the specific needs and production requirements of the business.

Manual corner rounding machines are a popular choice for businesses that require flexibility and customization in their cutting and punching processes. These machines are operated manually, requiring the user to feed the material into the machine and operate the cutting mechanism.

The advantage of manual corner rounding machines is their versatility. They can handle a wide range of materials, including paper, cardboard, plastic, and even thin metals. This makes them ideal for small businesses, craft shops, and print shops that deal with various materials and require precise and consistent corner rounding.

Manual corner rounding machines also offer a cost-effective solution for smaller-scale productions. They are generally more affordable than automatic machines and require less maintenance. Additionally, manual machines allow for instant adjustments and changes, making them perfect for on-demand customization and quick turnaround times.

While manual corner rounding machines may require more labor and time compared to automatic machines, they are an excellent choice for businesses that prioritize flexibility, customization, and cost-effectiveness in their corner rounding processes.

Automatic corner rounding machines are a game-changer for businesses that require high volume production and consistent results. These machines eliminate the need for manual operation, allowing for a more efficient and streamlined workflow. With their automated cutting and punching mechanisms, they can rapidly process a large number of materials, resulting in significant time savings.

One of the key benefits of automatic corner rounding machines is their ability to deliver precise and consistent cuts. These machines are equipped with advanced technology and programmable features, ensuring that every corner rounded is of the same quality and accuracy. This is especially crucial for industries that demand consistent finishing, such as printing and packaging.

In addition to time savings, automatic corner rounding machines also contribute to cost savings. By automating the cutting and punching processes, businesses can reduce labor costs and minimize the risk of human errors. The efficiency of these machines also leads to higher productivity, enabling businesses to take on more projects and increase their revenue.

When choosing an automatic corner rounding machine, it is important to consider factors such as the machine's capacity and size options, as well as its versatility and customization features. It is essential to select a machine that aligns with the specific needs and demands of your business to maximize its benefits.

In conclusion, automatic corner rounding machines offer significant advantages in terms of both time and cost savings. They provide efficient and precise cutting and punching capabilities, making them ideal for businesses that require high volume production and consistent results. Choosing the right machine that fits your business's requirements is crucial in maximizing these benefits and staying ahead in the competitive market.

Corner rounding machines not only provide efficiency and precision in cutting and punching, but they also offer significant cost savings for businesses. One of the key areas where cost savings can be achieved is through reduced material waste. With manual corner rounding methods, there is a higher risk of human error, leading to wasted materials and increased costs. However, automatic corner rounding machines eliminate this risk by delivering consistent and precise cuts every time, minimizing material waste and maximizing cost savings.

Additionally, corner rounding machines contribute to lower production costs by reducing the need for manual labor. With their automated cutting and punching mechanisms, these machines can perform tasks at a much faster rate, eliminating the need for additional manpower. This not only reduces labor costs but also increases productivity, allowing businesses to take on more projects and generate higher revenue.

By investing in a corner rounding machine, businesses can achieve significant cost savings in terms of material waste and labor expenses, making it a worthwhile investment for long-term profitability and success.

One of the key advantages of using corner rounding machines is the significant reduction in material waste. Unlike manual methods, which are prone to human error and inconsistent cutting, automatic corner rounding machines deliver precise and consistent cuts every time. This accuracy ensures that materials are utilized efficiently, minimizing waste and maximizing cost savings.

With manual methods, mistakes in cutting and punching can result in misaligned corners or uneven edges, leading to the need for additional materials to make up for the errors. This not only adds unnecessary expenses but also contributes to a higher environmental impact.

By investing in a corner rounding machine, businesses can greatly reduce material waste and optimize resource utilization. With consistent and accurate cuts, there is no need for excess materials, resulting in substantial cost savings and a more sustainable production process. Whether it's paper, plastic, or other materials, a corner rounding machine ensures that every piece is used efficiently, benefiting both the bottom line and the environment.

Lower production costs are another significant advantage of using corner rounding machines. These machines offer cost savings by improving the efficiency of the cutting and punching processes, reducing labor requirements, and minimizing material waste.

With manual methods, the cutting and punching tasks are often time-consuming and labor-intensive. This increases production costs as more manpower is needed to complete these tasks. Additionally, the margin for error is higher, leading to more material waste and the need for additional resources.

In contrast, corner rounding machines automate these processes, leading to faster production times and decreased labor costs. The machines operate with precision and consistency, eliminating the need for rework or redoing tasks due to errors. This not only saves time but also reduces the consumption of materials, resulting in cost savings.

By investing in corner rounding machines, businesses can streamline their production processes, reduce labor costs, and optimize resource utilization. This ultimately leads to lower production costs and increased profitability.

Time is a valuable resource in any production process, and corner rounding machines offer significant time savings. These machines are designed to increase production speed and streamline workflow processes, resulting in improved efficiency and productivity.

One of the key time-saving benefits of corner rounding machines is their increased production speed. These machines are equipped with advanced technology that allows for rapid cutting and punching of corners. Compared to manual methods, which can be time-consuming and labor-intensive, corner rounding machines can complete the same tasks in a fraction of the time. This allows businesses to meet tight deadlines and fulfill orders more quickly.

Furthermore, corner rounding machines contribute to a streamlined workflow. With manual methods, there is often a need for multiple steps and adjustments to achieve the desired rounded corner. In contrast, corner rounding machines automate these processes, reducing the time required for each task. This allows for a more efficient production process, minimizing downtime and maximizing productivity.

By investing in corner rounding machines, businesses can save valuable time, allowing them to increase production capacity, fulfill orders faster, and meet customer demands more efficiently. This ultimately leads to improved profitability and customer satisfaction.

One of the key advantages of using corner rounding machines is the significant increase in production speed. These machines are equipped with advanced technology that allows for rapid cutting and punching of corners. Compared to manual methods which can be time-consuming and labor-intensive, corner rounding machines can complete the same tasks in a fraction of the time.

By automating the corner rounding process, these machines eliminate the need for manual adjustments and multiple steps, resulting in a streamlined workflow. This not only saves time but also reduces the potential for errors and inconsistencies.

With increased production speed, businesses can meet tight deadlines and fulfill orders more quickly. This ultimately leads to improved customer satisfaction and increased profitability. Additionally, the time savings provided by corner rounding machines allow businesses to increase their production capacity, taking on more projects and expanding their customer base.

Investing in corner rounding machines can significantly boost productivity and efficiency in the production process, resulting in substantial time savings and enhanced business performance.

Streamlined workflow processes are another significant benefit of using corner rounding machines. These machines are designed to integrate seamlessly into existing production lines, ensuring a smooth and efficient workflow.

By automating the process of cutting and punching corners, corner rounding machines eliminate the need for manual adjustments and multiple steps. This reduces the risk of errors and inconsistencies that can occur when relying on manual labor.

Furthermore, corner rounding machines can be programmed to perform a wide range of tasks and configurations, allowing for customization and versatility in the production process. This flexibility enables businesses to easily adapt to different project requirements and meet customer demands efficiently.

With a streamlined workflow, businesses can optimize their production cycles, minimize downtime, and maximize productivity. This ultimately leads to cost savings and faster turnaround times, enhancing overall business performance and customer satisfaction. Investing in corner rounding machines can greatly improve workflow processes, making them an essential tool for any production facility.

When selecting a corner rounding machine for your business, it is important to consider several factors to ensure the machine meets your specific needs.

One key factor to consider is the capacity and size options of the machine. Assess the volume of production and the size of materials you will be working with to determine the appropriate machine size. This will help optimize efficiency and prevent any limitations in the production process.

Versatility and customization features are also crucial considerations. Look for machines that offer a variety of cutting and punching options, as well as adjustable settings. This will allow you to adapt the machine to different project requirements, enhancing flexibility and productivity.

Additionally, it is important to evaluate the machine's durability and reliability. Look for reputable brands and models that have a proven track record for long-lasting performance and minimal maintenance needs.

By carefully considering these factors, you can choose a corner rounding machine that aligns with your business needs, maximizes cost and time savings, and ultimately contributes to the overall success of your production operations.

When choosing a corner rounding machine, it is essential to consider its capacity and size options. Assessing the volume of production and the size of materials you will be working with is crucial in determining the appropriate machine size. This evaluation helps optimize efficiency by preventing any limitations in the production process.

A corner rounding machine with a larger capacity is suitable for businesses with high-volume production needs. On the other hand, if you primarily deal with smaller materials or have lower production requirements, a machine with a smaller capacity may be sufficient. It is important to strike the right balance to ensure smooth operations and avoid any bottlenecks in the workflow.

Moreover, versatility is key when it comes to size options. Look for machines that offer adjustable settings, allowing you to adapt the machine to different project requirements. This flexibility enhances productivity and ensures that the machine can handle a wide range of material sizes effectively.

By carefully considering the capacity and size options of a corner rounding machine, you can choose a machine that meets your specific production needs and maximizes efficiency in your workflow.

When selecting a corner rounding machine, it is important to consider the versatility and customization features it offers. These features allow you to optimize the machine's functionality according to your specific project requirements.

A versatile corner rounding machine should offer adjustable settings, allowing you to customize the cutting and punching parameters. This ensures that the machine can handle a wide range of material sizes and thicknesses effectively.

Additionally, look for machines that have interchangeable dies or cutting tools. This feature enables you to switch between different corner rounding sizes and shapes easily, giving you more flexibility in your design choices.

Moreover, some corner rounding machines have additional customization options such as adjustable punching pressure or speed control. These features allow you to tailor the machine's performance according to the material you are working with, ensuring precise and efficient results.

By choosing a corner rounding machine with versatility and customization features, you can adapt the machine to meet the specific needs of your projects, increasing efficiency and productivity in your workflow.

In conclusion, investing in a cutting and punching corner rounding machine can significantly contribute to cost and time savings in your business. These machines offer various benefits such as increased efficiency and precision in cutting and punching, reducing material waste, and lowering production costs. Additionally, they help to save time by increasing production speed and streamlining workflow processes.

When choosing a corner rounding machine, it is important to consider factors such as capacity and size options, as well as the versatility and customization features it offers. These features allow you to adapt the machine to your specific project requirements, further enhancing its efficiency and productivity.

By maximizing cost and time savings with corner rounding machines, businesses can optimize their operation and increase profitability. It is crucial to select the right machine that meets your specific needs and offers the desired features. With the right machine in place, you can streamline your corner rounding processes and achieve consistent, high-quality results.

Corner rounding machines offer businesses the opportunity to maximize cost and time savings. By investing in these machines, companies can optimize their production processes and increase profitability.

One of the key ways to achieve cost savings is through reduced material waste. Corner rounding machines are designed to cut and punch with precision, minimizing the amount of material needed for each project. This not only saves on material costs but also reduces waste, making the production process more sustainable.

In addition to cost savings, corner rounding machines also save time. With increased production speed, these machines can complete cutting and punching tasks efficiently, allowing businesses to meet deadlines and fulfill customer orders more quickly. Moreover, they streamline workflow processes by automating tasks that would otherwise be done manually, freeing up valuable time for employees to focus on other aspects of production.

By choosing the right corner rounding machine for their specific needs, businesses can maximize cost and time savings. These machines offer flexibility, customization features, and the ability to adapt to different project requirements, ensuring consistent, high-quality results. With cost and time savings in place, businesses can enhance their overall operation and achieve greater success.

When it comes to choosing the right corner rounding machine for your business, there are a few factors to consider. First and foremost, you need to assess the capacity and size options that the machine offers. Take into account the size and quantity of the materials you typically work with, and ensure that the machine can accommodate your needs.

Another important factor is versatility and customization features. Look for a machine that can adapt to different project requirements, allowing you to achieve the desired results every time. This includes the ability to adjust cutting and punching sizes, as well as the option to add additional features like perforation or scoring.

Additionally, consider the machine's reliability, durability, and ease of use. You want a machine that is efficient and requires minimal maintenance, allowing your production process to run smoothly.

Lastly, it is crucial to evaluate the cost of the machine and its potential return on investment. While it is important to find a machine within your budget, make sure to weigh it against the cost savings and increased productivity it can offer.

By carefully considering these factors, you can choose the right corner rounding machine that will maximize cost and time savings for your business while delivering high-quality results.

Enhancing Efficiency and Precision: The Cutting and Punching Corner Rounding Machine

The cutting and punching corner rounding machine is a valuable tool in various industries, providing enhanced efficiency and precision in corner rounding processes. This machine combines cutting and punching capabilities, making it a versatile option for manufacturers and fabricators.

Efficiency and precision are crucial factors in any production process, as they directly impact the quality of the end product and the overall productivity of the operation. With the cutting and punching corner rounding machine, manufacturers can streamline their production processes and achieve consistent, high-quality results.

By investing in a corner rounding machine, companies can benefit from increased efficiency, reduced production time, and minimized material waste. Moreover, the precision offered by this machine ensures that every corner is rounded accurately and uniformly, enhancing the overall appearance and functionality of the finished product.

In the following sections, we will explore the functionality of the corner rounding machine, its advantages, and the top features to look for. We will also highlight the industries that can benefit from implementing this technology. Let's dive in!

The cutting and punching corner rounding machine is a versatile tool that combines cutting and punching capabilities to streamline the corner rounding process. This machine is designed to enhance efficiency and precision in various industries. It offers a range of features and functions that allow manufacturers and fabricators to achieve consistent and high-quality results.

The cutting functionality of the machine enables precise and clean cuts, ensuring that corners are neatly rounded. Additionally, the punching capabilities make it possible to create rounded corners in a variety of materials, including paper, cardboard, plastic, and metal.

This machine is equipped with advanced automation and programmable settings, allowing for greater control and customization in the corner rounding process. It also offers versatility in corner rounding options, enabling users to choose different radii and styles.

By investing in a cutting and punching corner rounding machine, companies can significantly improve their production processes, minimize material waste, and achieve precise and uniform corner rounding. This ultimately leads to enhanced efficiency, productivity, and the production of high-quality products.

Enhancing efficiency and precision is of utmost importance in any industry. It directly affects the overall productivity, quality, and cost-effectiveness of the production processes. This is especially true when it comes to corner rounding, where precision is crucial to achieve consistent and aesthetically pleasing results.

By investing in a cutting and punching corner rounding machine, companies can significantly improve their production processes. These machines are equipped with advanced automation and programmable settings, allowing for greater control and customization. With the ability to set precise measurements and configurations, manufacturers can reduce errors and material waste.

Efficient corner rounding also has a direct impact on the overall production cycle time. With a high-speed machine that combines cutting and punching capabilities, manufacturers can streamline the corner rounding process, leading to shorter lead times and increased productivity.

Moreover, enhancing precision ensures that every product meets the required specifications and quality standards. With consistent and uniform corner rounding, companies can produce high-quality products that are visually appealing and meet customer expectations.

In summary, investing in a cutting and punching corner rounding machine is essential for companies looking to enhance efficiency and precision in their production processes. This not only improves productivity and minimizes material waste but also ensures consistent and high-quality results.

The functionality of a corner rounding machine revolves around its cutting and punching capabilities. These machines are designed to efficiently and precisely round the corners of various materials, such as paper, cardboard, plastic, and metal.

Through their cutting features, corner rounding machines can trim excess material and create a smooth and visually appealing curve. The machines offer different cutting options, allowing users to select the desired radius and angle for each corner. This customization ensures that the final product meets specific requirements and achieves the desired aesthetic.

Additionally, corner rounding machines incorporate punching capabilities, enabling the creation of holes or slots in the rounded corners. This feature is particularly useful in applications where fastening or threading is necessary, such as in packaging or fabrication processes.

The cutting and punching functionalities of these machines are performed with precision and consistency, ensuring that each corner is uniformly rounded. This not only enhances the overall appearance of the product but also avoids any potential safety hazards caused by sharp edges.

In conclusion, corner rounding machines offer a comprehensive solution for achieving rounded corners in various materials, providing efficiency, precision, and versatility in the production processes.

The cutting features and capabilities of a corner rounding machine play a crucial role in achieving precise and smooth curved edges. These machines offer a range of cutting options, allowing users to customize the radius and angle of each corner. This flexibility ensures that the final product meets specific requirements and achieves the desired aesthetic.

Corner rounding machines are equipped with advanced cutting mechanisms that efficiently trim excess material and create consistent curves. The cutting process is performed with precision and accuracy, resulting in uniform rounded corners throughout the material.

Furthermore, corner rounding machines can handle various materials, including paper, cardboard, plastic, and metal. This versatility enables users to apply corner rounding in a wide range of applications across different industries.

By utilizing the cutting features and capabilities of a corner rounding machine, manufacturers can enhance the visual appeal of their products and eliminate any potential safety hazards caused by sharp edges. These machines provide a reliable and efficient solution for achieving precisely rounded corners.

The punching capabilities of a corner rounding machine are another essential feature that enhances its efficiency and precision. These machines are designed to handle a variety of materials, including paper, cardboard, plastic, and even metal. This versatility allows manufacturers in different industries to implement corner rounding in their production processes.

When it comes to punching, corner rounding machines utilize advanced mechanisms to create clean and accurate holes. The machines can punch holes of different sizes and shapes, depending on the specific requirements of the project. This capability enables users to achieve consistent and professional-looking results.

Furthermore, the punching capabilities of corner rounding machines also contribute to the overall efficiency of the production process. With the ability to punch holes in a single operation, these machines save time and effort, streamlining the workflow and increasing productivity.

By investing in a corner rounding machine with excellent punching capabilities, manufacturers can ensure that their products feature precise and neatly punched holes, enhancing both the visual appeal and functionality of the finished items.

Investing in a corner rounding machine offers numerous advantages that can significantly enhance the efficiency and precision of production processes. Firstly, these machines greatly increase the speed and productivity of corner rounding operations. With automated features and programmable settings, manufacturers can streamline their workflow and save valuable time and resources.

Moreover, corner rounding machines ensure enhanced precision and consistency in the corner rounding process. By utilizing advanced cutting and punching mechanisms, these machines produce clean and accurate results, eliminating the risk of human error. This not only improves the overall quality of the finished products but also enhances their visual appeal.

Additionally, corner rounding machines offer versatility in corner rounding options, allowing manufacturers to handle different materials and customize the size and shape of corner rounding. This flexibility is particularly beneficial for industries such as printing, packaging, and metalworking, where diverse materials and designs are common.

By investing in a corner rounding machine, manufacturers can achieve increased efficiency, higher precision, and greater flexibility, ultimately leading to improved productivity and customer satisfaction.

Investing in a corner rounding machine offers manufacturers a significant boost in efficiency when it comes to production processes. These machines are designed to streamline workflow and save valuable time and resources. With automated features and programmable settings, manufacturers can achieve higher productivity rates and meet tight timelines. The corner rounding machine eliminates the need for manual labor and reduces the risk of human error, ensuring consistent and accurate results every time. These machines can handle high volumes of corner rounding tasks, increasing overall output and reducing production time. Additionally, the automated nature of these machines allows for continuous operation, allowing manufacturers to maximize their productivity. By investing in a corner rounding machine, manufacturers can optimize their production processes, minimize downtime, and increase their overall efficiency levels.

Investing in a corner rounding machine not only improves efficiency but also offers enhanced precision and consistency in corner rounding tasks. These machines are equipped with advanced technology and features that ensure precise cutting and punching of corners on various materials.

With programmable settings and automated processes, manufacturers can achieve consistent results on every corner rounding task. The machine's accuracy eliminates the risk of human error and ensures that each rounded corner is precise and uniform.

Furthermore, corner rounding machines have the ability to maintain a consistent cutting depth and punching force throughout the production process. This consistency minimizes variations in corner roundings and ensures a high level of precision, which is especially crucial in industries that require exact specifications.

By investing in a corner rounding machine, manufacturers can achieve a higher level of precision and consistency in their corner rounding tasks, resulting in improved quality of finished products and customer satisfaction.

When investing in a corner rounding machine, it is essential to consider the top features that can enhance efficiency and precision. These features can significantly impact the quality and productivity of your corner rounding tasks.

One crucial feature is automation and programmable settings. This allows for precise and consistent cutting and punching, eliminating human error and ensuring uniform results. Look for machines with advanced control panels that offer customizable settings and easy programming options.

Versatility in corner rounding options is another key feature to consider. A machine that can handle various materials and sizes of corners will provide flexibility in your production processes. Look for machines that offer adjustable cutting depth and punching force to accommodate different requirements.

Additionally, ensure that the machine is constructed with high-quality materials and has a sturdy build. This ensures durability and longevity, allowing for long-term use without frequent breakdowns or maintenance.

By considering these top features, you can choose a corner rounding machine that provides maximum efficiency and precision for your specific needs, ultimately improving your overall productivity and profitability.

Automation and programmable settings are crucial features to consider when investing in a corner rounding machine. These features enhance efficiency and precision by eliminating human error and ensuring consistent results. The advanced control panels of modern corner rounding machines offer customizable settings, allowing users to program the machine according to their specific requirements.

With automation and programmable settings, users can easily set the cutting depth and punching force, ensuring uniformity in the corner rounding process. This eliminates the need for manual adjustments and reduces the time required for each task. The precision achieved through programmable settings also ensures that each corner is accurately rounded, resulting in high-quality finished products.

Moreover, automation allows for increased production speed, as the machine can operate continuously without the need for constant manual intervention. This feature is especially valuable in high-volume production settings, where time savings directly impact productivity and profitability.

By investing in a corner rounding machine with automation and programmable settings, businesses can enhance efficiency, reduce human error, and achieve consistent, precise results in their corner rounding tasks.

When investing in a corner rounding machine, it is essential to consider its versatility in corner rounding options. A versatile machine offers a wide range of possibilities, allowing users to meet different corner rounding requirements in various industries.

One aspect of versatility to look for is the ability to round corners of different sizes and shapes. The machine should be able to handle corners with different radii and angles, accommodating diverse design specifications. Additionally, adjustable cutting and punching tools are crucial to adapt to different materials, such as paper, plastic, or metal.

Moreover, the machine should offer options for both single corner rounding and multiple corner rounding. This flexibility allows users to perform corner rounding tasks on individual pieces or batch processing, saving time and effort.

A corner rounding machine with versatile options empowers businesses to cater to a wide range of applications, making it a valuable asset in industries like printing and packaging, metalworking, and fabrication.

Corner rounding machines are utilized in various applications and industries that require precise and efficient corner rounding. One prominent industry is the printing and packaging industry, where these machines are used to round corners on business cards, brochures, and packaging materials. The ability to achieve consistent and professional-looking rounded corners adds value and aesthetic appeal to printed materials.

In addition, corner rounding machines find applications in the metalworking and fabrication industries. These machines excel at rounding corners on metal sheets, plates, and profiles, enabling the fabrication of products with smooth and safe edges. This is particularly useful in industries such as automotive, aerospace, and construction, where rounded corners enhance safety and functionality.

The versatility of corner rounding machines also makes them suitable for various manufacturing processes, including the production of furniture, signage, and electronic components. With their ability to handle different materials and corner specifications, these machines enable businesses in diverse industries to achieve efficient production processes and deliver high-quality products to their customers.

Corner rounding machines have become an invaluable tool in the printing and packaging industry. Businesses in this sector rely on these machines to round corners on various materials, such as business cards, brochures, and packaging materials. The ability to achieve consistent and professional-looking rounded corners adds value and aesthetic appeal to printed materials, making them more visually appealing to customers.

In the printing and packaging industry, where efficiency is crucial, corner rounding machines offer significant benefits. These machines can handle high volumes of materials, ensuring fast and efficient production processes. They also provide precise and consistent results, eliminating errors and reworks that can delay production timelines. With corner rounding machines, businesses in the printing and packaging industry can meet strict deadlines while delivering high-quality products to their clients.

Moreover, corner rounding machines offer versatility in corner specifications, allowing printing and packaging companies to cater to various design preferences and customer requirements. Whether it's for a sleek and modern look or a softer and more rounded appearance, corner rounding machines can adapt to different styles and produce customized results.

By investing in corner rounding machines, businesses in the printing and packaging industry can enhance their efficiency and deliver visually appealing products that meet customer expectations. These machines are an essential tool for achieving high-quality printing and packaging solutions in a competitive market.

The use of corner rounding machines is not limited to the printing and packaging industry. These machines have also found valuable applications in the metalworking and fabrication processes.

In metalworking, corner rounding machines are used to remove sharp edges and create smooth, rounded corners on various metal components. This is particularly important in industries such as automotive, aerospace, and manufacturing, where precision and safety are paramount. By rounding corners, these machines eliminate the risk of injuries caused by sharp edges and improve the overall safety of the finished products.

Furthermore, corner rounding machines enhance the aesthetic appeal of metal components, making them look more polished and professional. This is crucial for industries that rely on visually appealing products, such as the furniture and interior design sectors.

The versatility of corner rounding machines allows them to be used on a wide range of metals, including steel, aluminum, and brass. They can handle various thicknesses and sizes of metal components, making them a versatile tool in metal fabrication processes.

By incorporating corner rounding machines into their workflow, metalworking and fabrication companies can achieve higher efficiency, precision, and safety in their operations. These machines automate the process of rounding corners, reducing the need for manual labor and ensuring consistent and high-quality results. The use of corner rounding machines in metalworking and fabrication processes not only streamlines production but also adds value to the finished products.

In conclusion, the use of corner rounding machines in metalworking and fabrication processes offers numerous advantages. These machines improve efficiency and precision, resulting in higher-quality and safer products. By automating the process of rounding corners, these machines streamline production and reduce the need for manual labor. The consistent and precise results obtained through corner rounding machines enhance the overall aesthetic appeal of metal components, adding value to the finished products.

Furthermore, the versatility of corner rounding machines allows them to be used on various metals and different sizes of components, providing flexibility in the fabrication process.

As technology continues to advance, it is expected that corner rounding machines will become even more sophisticated, offering advanced automation and programmable settings. This will further enhance efficiency and precision in metalworking and fabrication processes.

Incorporating corner rounding machines into metalworking and fabrication workflows is a wise investment for companies seeking to improve production efficiency, maintain high-quality standards, and prioritize safety. With the numerous benefits they offer, corner rounding machines are becoming an essential tool in the metalworking industry.

The utilization of corner rounding machines in metalworking and fabrication processes offers significant benefits in terms of efficiency and precision. These machines improve production efficiency by automating the process of rounding corners, reducing the need for manual labor. This streamlines the production workflow and allows for faster and more consistent results. Additionally, corner rounding machines enhance precision and consistency in corner rounding, resulting in higher-quality and safer products. The use of these machines ensures that each component has the same rounded corner shape and size, adding to the overall aesthetic appeal of the finished products. By investing in a corner rounding machine, companies can achieve reliable and precise corner rounding results, leading to improved efficiency and a higher standard of quality in their metalworking and fabrication processes.

In the constantly evolving world of technology, corner rounding machines are also experiencing advancements and innovations. The future holds promising trends that will further enhance the efficiency and precision of these machines.

One of the future trends in corner rounding machine technology is the integration of artificial intelligence (AI) and machine learning capabilities. This will enable the machines to analyze data and make autonomous decisions, optimizing the corner rounding process based on various factors such as material type and thickness.

Another trend is the development of more compact and portable corner rounding machines. These machines will be easier to transport and set up in different work environments, allowing for greater flexibility and convenience.

Furthermore, there is a growing focus on improving energy efficiency and sustainability in corner rounding machines. Manufacturers are exploring new technologies and materials that reduce energy consumption and minimize environmental impact without compromising on performance.

As technology continues to advance, the future of corner rounding machines looks promising, with increased automation, portability, and eco-friendly features on the horizon. These advancements will further improve production efficiency and precision in metalworking and fabrication processes.

Efficiency Redefined: The Top Benefits of Electro Deburring Machines in Production

|

Understanding Electro Deburring Machines Increased Production Efficiency |

Electro deburring machines are advanced tools used in the manufacturing industry to remove burrs, sharp edges, and other imperfections from workpieces. These machines utilize electrical current for the deburring process, making them highly effective and efficient.

Electro deburring machines work by passing an electrical current through a conductive electrolyte solution. The workpiece is immersed in the solution, and when the current flows, it selectively removes the unwanted material from the edges and corners of the workpiece. This process helps in achieving a smooth and uniform surface finish.

These machines offer several advantages in production processes. They enhance production speed by quickly removing burrs, reducing manual labor requirements, and increasing overall efficiency. Additionally, electro deburring machines provide cost-effectiveness by minimizing scrap rates and improving product quality.

Overall, understanding electro deburring machines is crucial for manufacturers looking to streamline their production processes and achieve superior finishing results. By utilizing this advanced technology, manufacturers can enhance their productivity, optimize product quality, and stay ahead in a competitive market.

Electro deburring machines are advanced tools used in the manufacturing industry to remove burrs, sharp edges, and other imperfections from workpieces. These machines utilize electrical current for the deburring process, making them highly effective and efficient. The use of electro deburring machines has revolutionized the production process by significantly reducing manual labor and improving overall productivity.

These machines work by passing an electrical current through a conductive electrolyte solution, which selectively removes unwanted material from the edges and corners of the workpiece. This process ensures a smooth and uniform surface finish, enhancing product quality.

Electro deburring machines offer numerous benefits to manufacturers. They increase production efficiency by speeding up the deburring process, reducing downtimes, and minimizing scrap rates. Moreover, these machines are versatile and adaptable, suitable for various materials and workpiece shapes. Additionally, electro deburring machines contribute to environmental sustainability by reducing waste generation and operating energy-efficiently.

Overall, electro deburring machines have become essential equipment in modern manufacturing facilities, providing manufacturers with numerous advantages in terms of efficiency, quality improvement, versatility, and environmental sustainability.

Electro deburring machines work by utilizing electrical current in a conductive electrolyte solution to remove burrs and imperfections from workpieces. The process begins by immersing the workpiece in the electrolyte solution, which acts as a medium for the electrical current. Next, electrodes are placed strategically around the workpiece, creating an electric circuit.

When the current is applied, it flows through the electrolyte and removes material selectively from the edges and corners of the workpiece. This occurs due to the electrolytic action between the workpiece and the electrode. The unwanted material is dissolved in the electrolyte solution, leaving behind a smooth and uniform surface finish.

To ensure optimal deburring results, various factors such as voltage, current density, and dwell time are carefully controlled. These machines often have programmable settings that allow manufacturers to customize the deburring process according to their specific requirements.

Overall, electro deburring machines offer an efficient and precise solution for removing burrs and improving the quality of manufactured components.

Electro deburring machines have revolutionized the production process by significantly increasing efficiency. With their ability to remove burrs and imperfections quickly and accurately, these machines streamline operations and enhance overall productivity.

One of the key benefits of electro deburring machines is their ability to enhance production speed. The precision and speed at which the machines can remove burrs from workpieces result in faster turnaround times. This allows manufacturers to meet tight deadlines and increase their output without compromising quality.

Additionally, electro deburring machines offer cost-effectiveness in production processes. By automating the deburring process, companies can reduce labor costs and minimize the risk of human errors. This leads to improved overall efficiency while reducing downtime and rework.

By incorporating electro deburring machines into their production processes, manufacturers can achieve higher productivity levels, reduce costs, and optimize their operations. These machines truly redefine the efficiency of manufacturing processes by delivering consistent results in a shorter timeframe.

Electro deburring machines have revolutionized the production process by significantly increasing efficiency. These machines offer enhanced production speed, allowing manufacturers to meet tight deadlines and increase their output without compromising quality.

With their precision and speed, electro deburring machines can quickly remove burrs and imperfections from workpieces. This streamlined process minimizes the time required for deburring, resulting in faster turnaround times and increased productivity.

By automating the deburring process, companies can also reduce labor costs and minimize the risk of human errors. The machines consistently deliver high-quality results in a shorter timeframe, eliminating the need for manual deburring and reducing overall production time.

Overall, electro deburring machines contribute to a more efficient manufacturing process by enhancing production speed. Their ability to swiftly and accurately remove burrs translates into improved productivity, enabling companies to meet customer demands and achieve higher output levels.

Cost-effectiveness is a crucial aspect of any production process, and electro deburring machines offer significant cost-saving benefits. These machines eliminate the need for manual labor in the deburring process, reducing labor costs and minimizing the risk of human errors. By automating the deburring process, companies can achieve higher output levels without increasing their workforce.

Moreover, electro deburring machines provide consistent and reliable results, minimizing the chances of rework or rejection. This means manufacturers can save on material costs and avoid delays in production due to quality issues.

In addition, electro deburring machines have a longer service life compared to manual deburring methods. This reduces maintenance and replacement costs, making them a cost-effective investment in the long run.

Overall, the use of electro deburring machines increases cost-effectiveness by reducing labor costs, improving productivity, minimizing rework, and extending machine lifespan. Manufacturers can enjoy greater profitability while maintaining high-quality standards in their production processes.

Electro deburring machines offer significant benefits when it comes to quality improvement in manufacturing processes. These machines provide consistent and precise finishing results, ensuring that every workpiece is deburred to the required specifications. The automated nature of electro deburring eliminates the risk of human errors and ensures uniformity in the finished products.

By using electro deburring machines, manufacturers can reduce the chances of damage to workpieces. Manual deburring methods may result in accidental scratches or dents, leading to rework or rejection. However, electro deburring machines use controlled electrical currents to remove burrs without causing any harm to the workpiece surface.

With improved quality control, manufacturers can minimize wastage and optimize production output. By eliminating inconsistencies and defects, electro deburring machines contribute to a higher level of overall product quality. This directly translates into customer satisfaction and helps businesses maintain their reputation for delivering high-quality products.

In summary, electro deburring machines play a crucial role in enhancing quality standards, reducing defects, and ensuring consistent and reliable finishing results in the manufacturing industry.

Electro deburring machines are known for delivering consistent finishing results in manufacturing processes. These machines ensure that every workpiece is deburred to the required specifications with a high level of accuracy and precision.

The automated nature of electro deburring eliminates the risk of human errors and ensures uniformity in the finished products. Manufacturers can rely on these machines to consistently produce smooth and polished surfaces, enhancing the overall appearance and quality of their products.

By providing consistent finishing results, electro deburring machines contribute to improved quality control in the manufacturing industry. They eliminate inconsistencies and defects, resulting in higher product quality and customer satisfaction. This helps businesses maintain their reputation for delivering high-quality products and gain a competitive edge in the market.

Furthermore, consistent finishing results also facilitate efficient production planning and workflow management. Manufacturers can confidently schedule their production processes without worrying about variations in finishing outcomes. Electro deburring machines enable seamless integration into existing production systems, ensuring a smooth and reliable manufacturing operation.

Electro deburring machines provide manufacturers with the benefit of reducing the risk of damage to workpieces during the deburring process. The automated nature of these machines ensures that the deburring operation is performed consistently and accurately, minimizing the potential for human errors that can result in workpiece damage.

The use of electrochemical deburring also eliminates the need for manual handling of the workpieces, further reducing the risk of accidental damage or mishandling. This is especially beneficial when working with delicate or intricate parts that require careful handling to avoid any compromise in their structural integrity.